AEROSPACE

In today’s world, quality and precision play a crucial role in the aerospace and space industry. From commercial aircraft to spacecraft, every component must be manufactured with top-notch precision and durability to ensure safety and efficiency. Our company leads in the production of parts for these sectors, utilizing CNC turning and 5-axis milling technology.

Elevating precision to new heights.

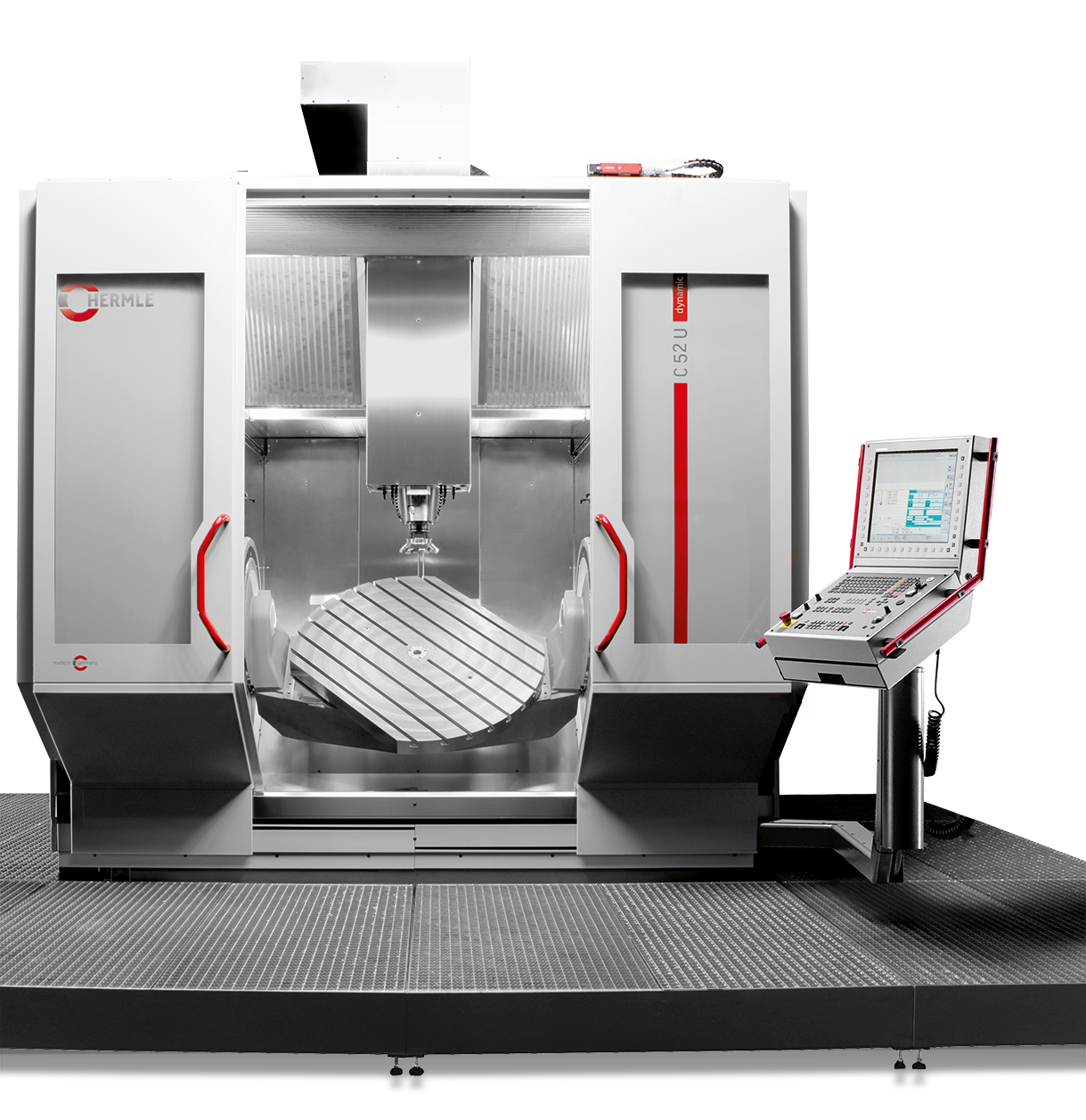

CNC Technology: The Foundation of Our Manufacturing

A key aspect of our manufacturing is the use of CNC (Computer Numerical Control) technology. This technology enables us to produce parts with exceptional precision and repeatability. CNC machines are essential for achieving the high standards required in the aerospace and space industry.

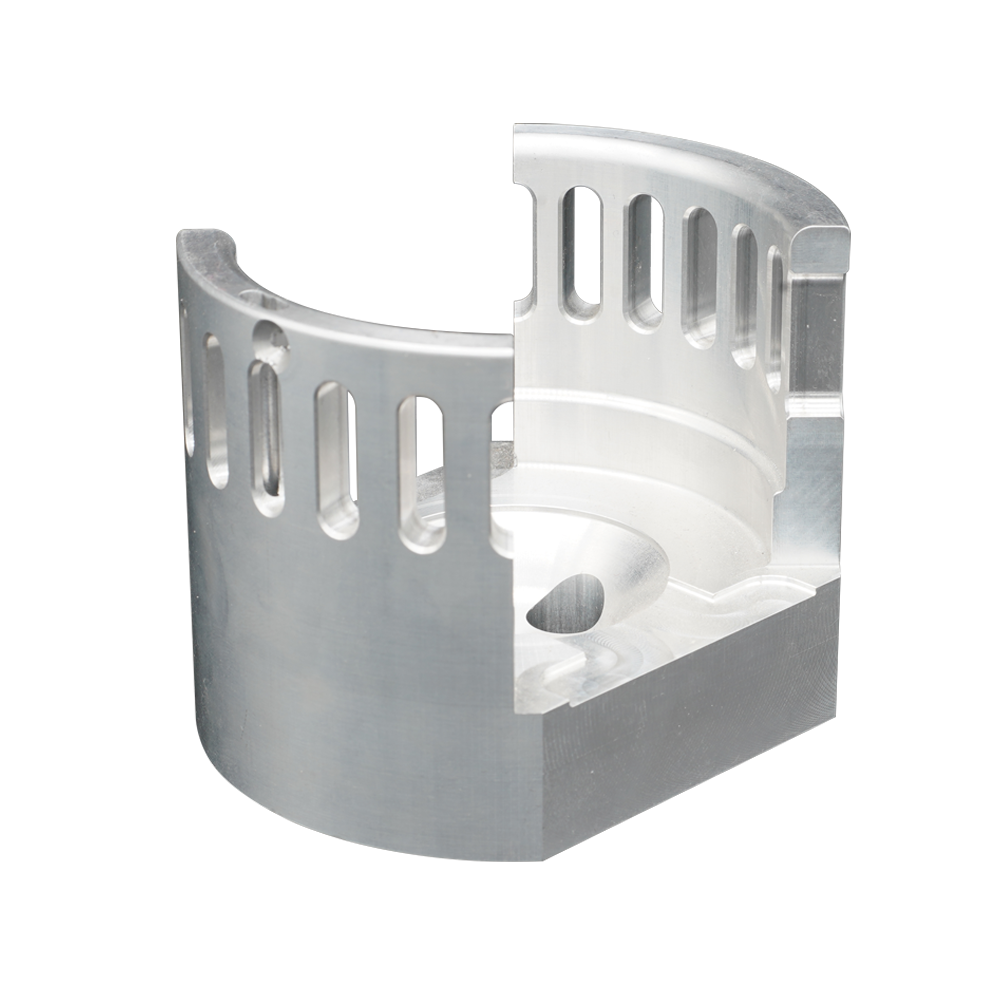

Turning and 5-Axis Milling: Our Tools for Perfection

Our manufacturing employs state-of-the-art material processing techniques, including turning and 5-axis milling. Turning allows us to create parts with cylindrical or conical shapes, while 5-axis milling enables the production of complex 3D shapes with high precision. These techniques allow us to create parts that meet the most stringent industry requirements.

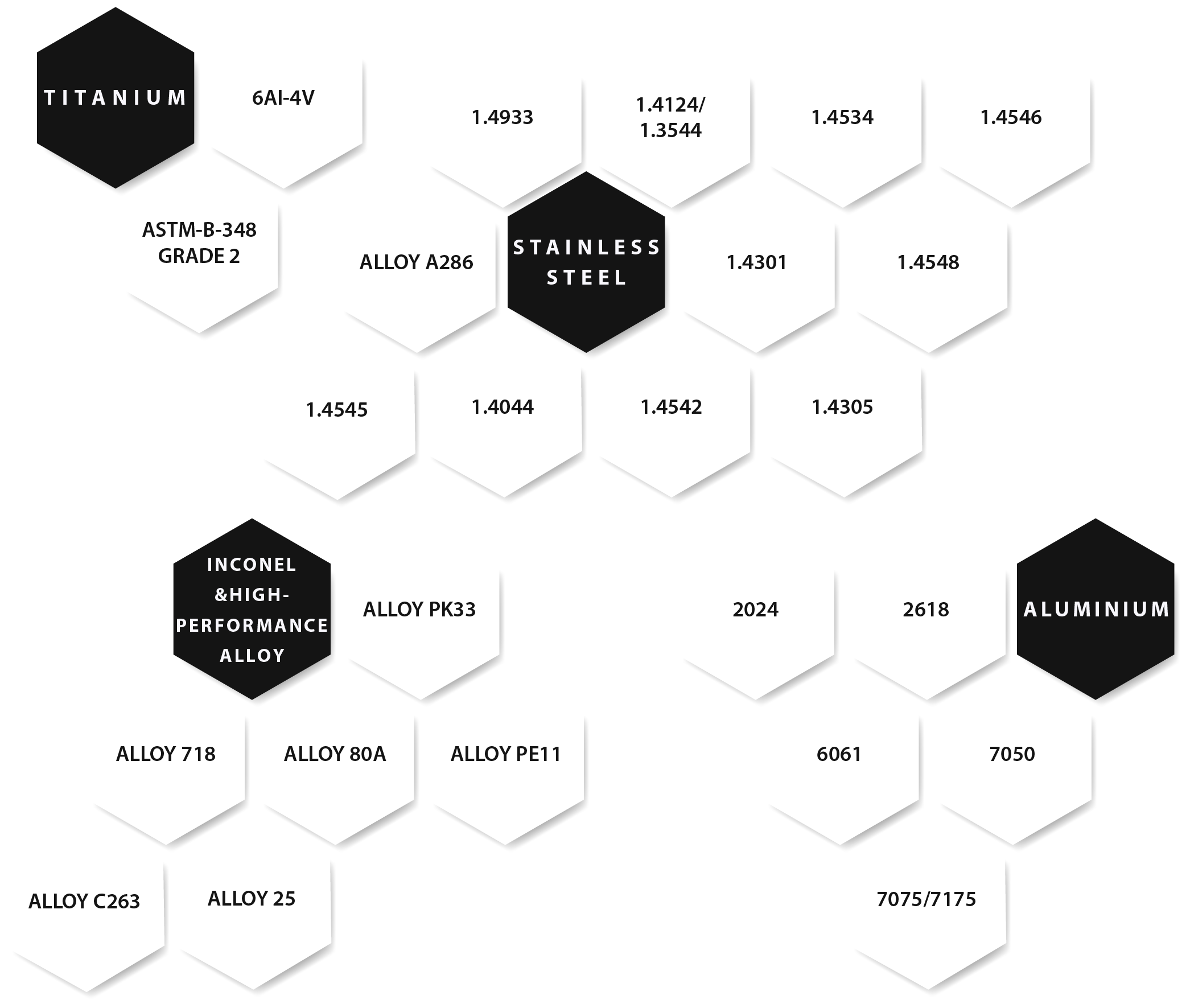

Special Materials

In the aerospace industry, a diverse range of materials is essential for manufacturing various components, including cabin, structural parts, and engine elements. These materials include high-strength steels for their durability and nickel-based alloys for their resistance to extreme temperatures. The selection and processing of these materials are critical to meet the stringent standards for quality, safety, and performance in aviation, ensuring the development of reliable and efficient aircraft components. For more detailed insights into the materials and processes used in aerospace manufacturing, visiting specialized industry websites can provide comprehensive information.

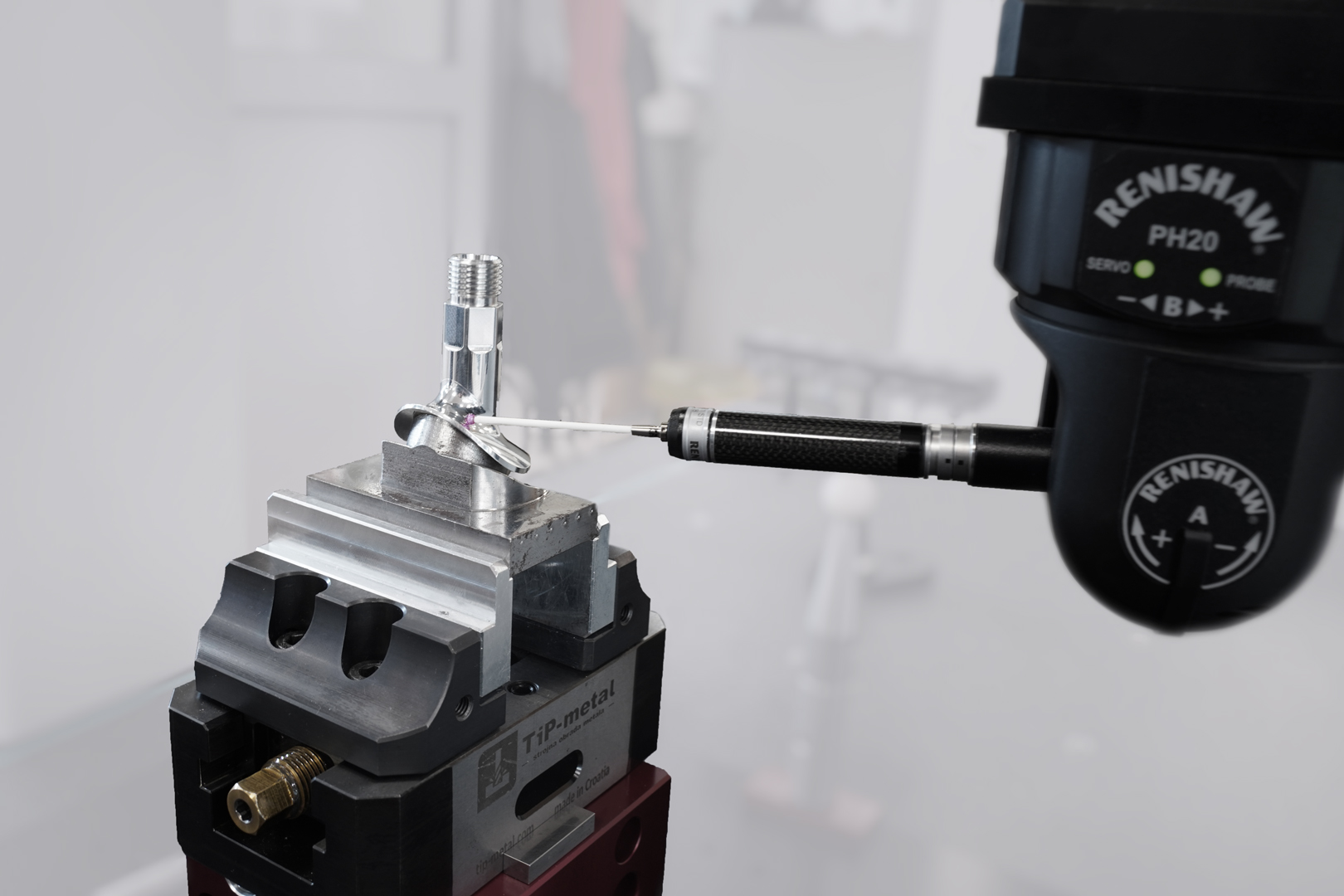

Strict Standards and Procedure

The focus is on rigorous quality management and assurance, emphasizing high standards in product development and manufacturing. Continuous improvement and technological advancements play a critical role in maintaining quality, customer satisfaction, and delivery reliability. The company employs advanced measurement and inspection methods, including modern CAQ systems and CMM systems, ensuring precise component quality and process traceability

Mobil:

Mobil: