Engineering

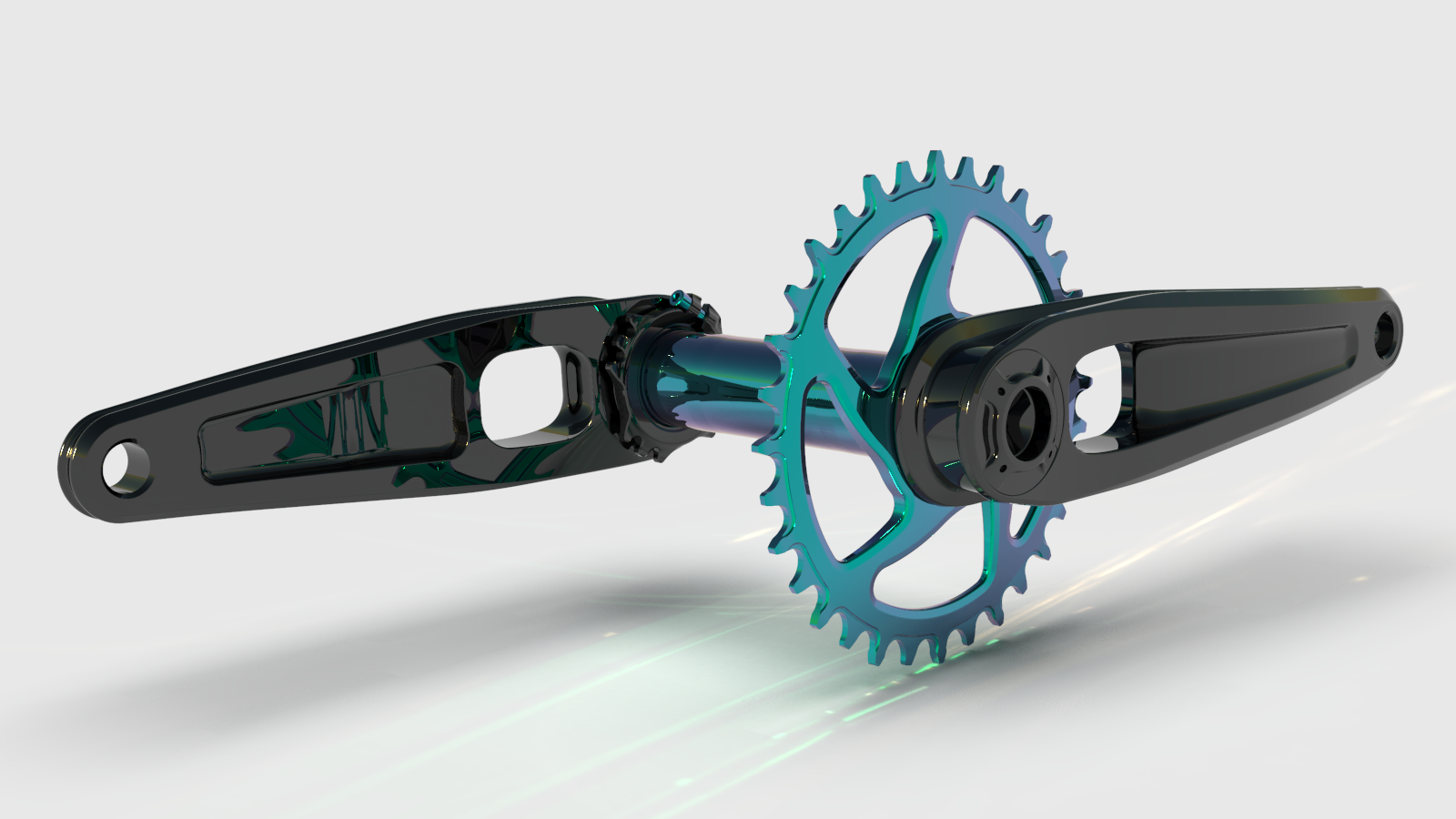

At AlfaTeh GmbH, we understand the importance of precision engineering in today’s competitive market. Engineering is at the core of everything we do. Our team of highly skilled engineers brings a wealth of expertise and ingenuity to every project, from concept to completion. With a focus on innovation and problem-solving, we tackle the most complex challenges head-on, utilizing advanced techniques and cutting-edge technology to deliver solutions that surpass expectations.

R&D: Research and Development

Driving Innovation Forward

Our R&D team is constantly exploring new materials, processes, and techniques, pushing the boundaries of what’s possible in metal fabrication. Whether it’s investigating the properties of advanced alloys, refining surface treatments for enhanced durability, or developing novel manufacturing methods for improved efficiency, our R&D efforts lay the groundwork for the next generation of solutions.

We are committed to understanding and anticipating the needs of our customers. R&D initiatives are guided by insights gleaned from client feedback, market trends, and industry benchmarks, enabling us to develop tailored solutions that address specific challenges and deliver tangible value. Whether it’s optimizing production processes to reduce lead times, enhancing product performance to meet stringent requirements, or introducing new features to drive competitive advantage, our customer-centric approach ensures that our R&D efforts are aligned with real-world needs and objectives.

Innovation is not a one-time event—it’s a journey of continuous improvement. Our R&D process is characterized by iterative cycles of experimentation, evaluation, and refinement, enabling us to evolve and adapt in response to changing demands and emerging opportunities. By embracing a culture of continuous improvement, we strive to stay at the forefront of technological innovation, delivering solutions and set new standards in metal fabrication.

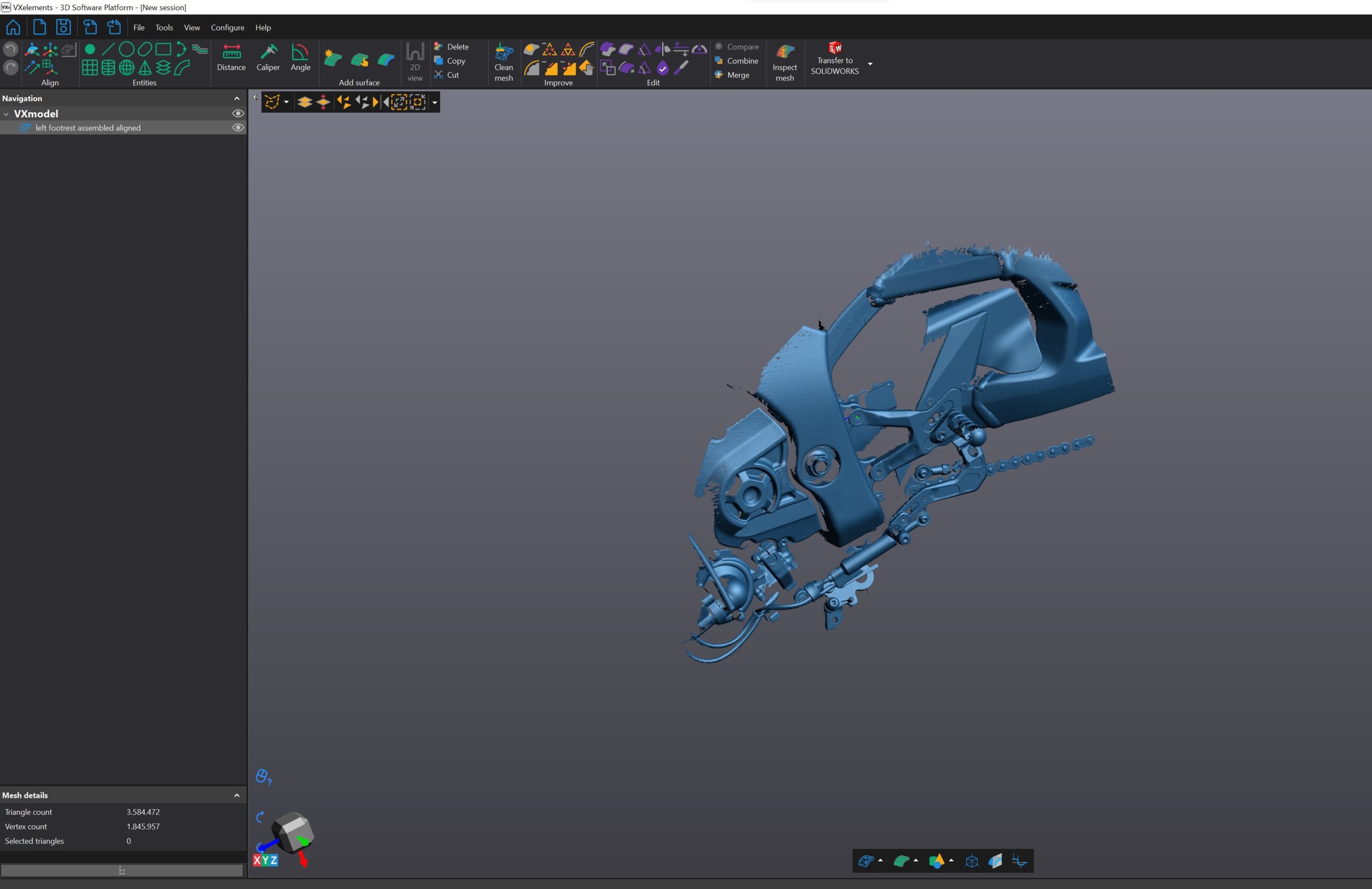

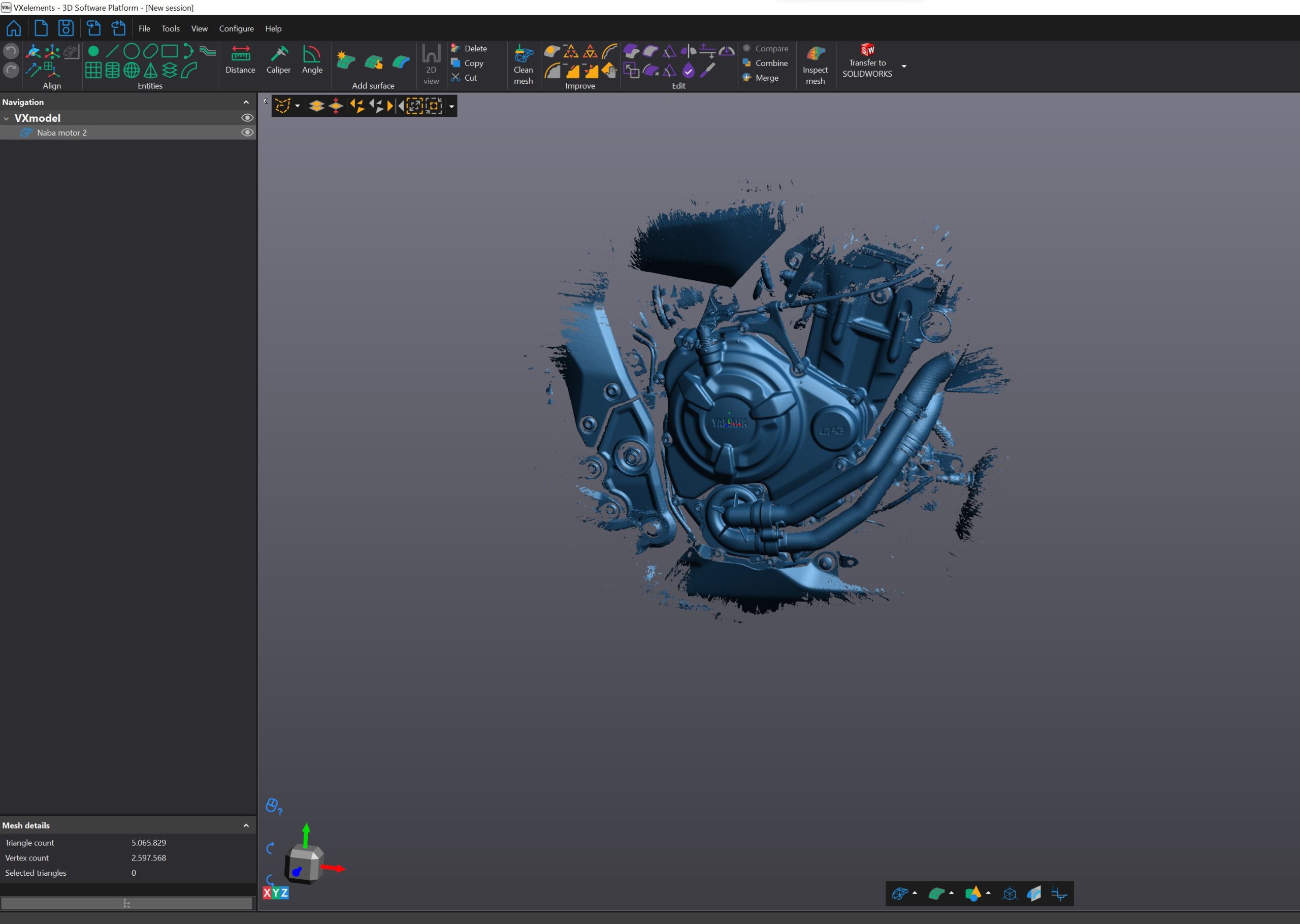

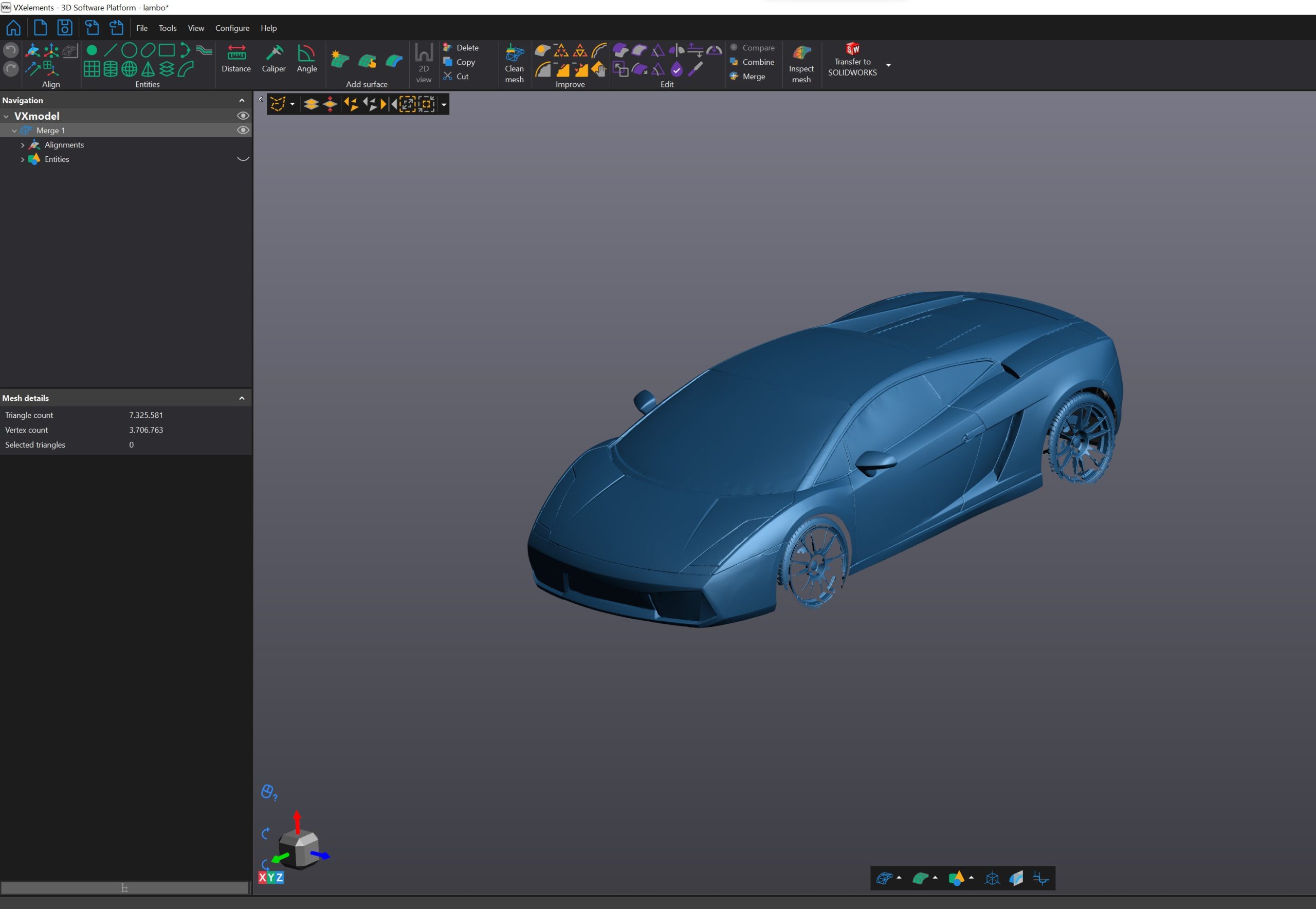

3D Scanning

Precision Measurement, Seamless Integration

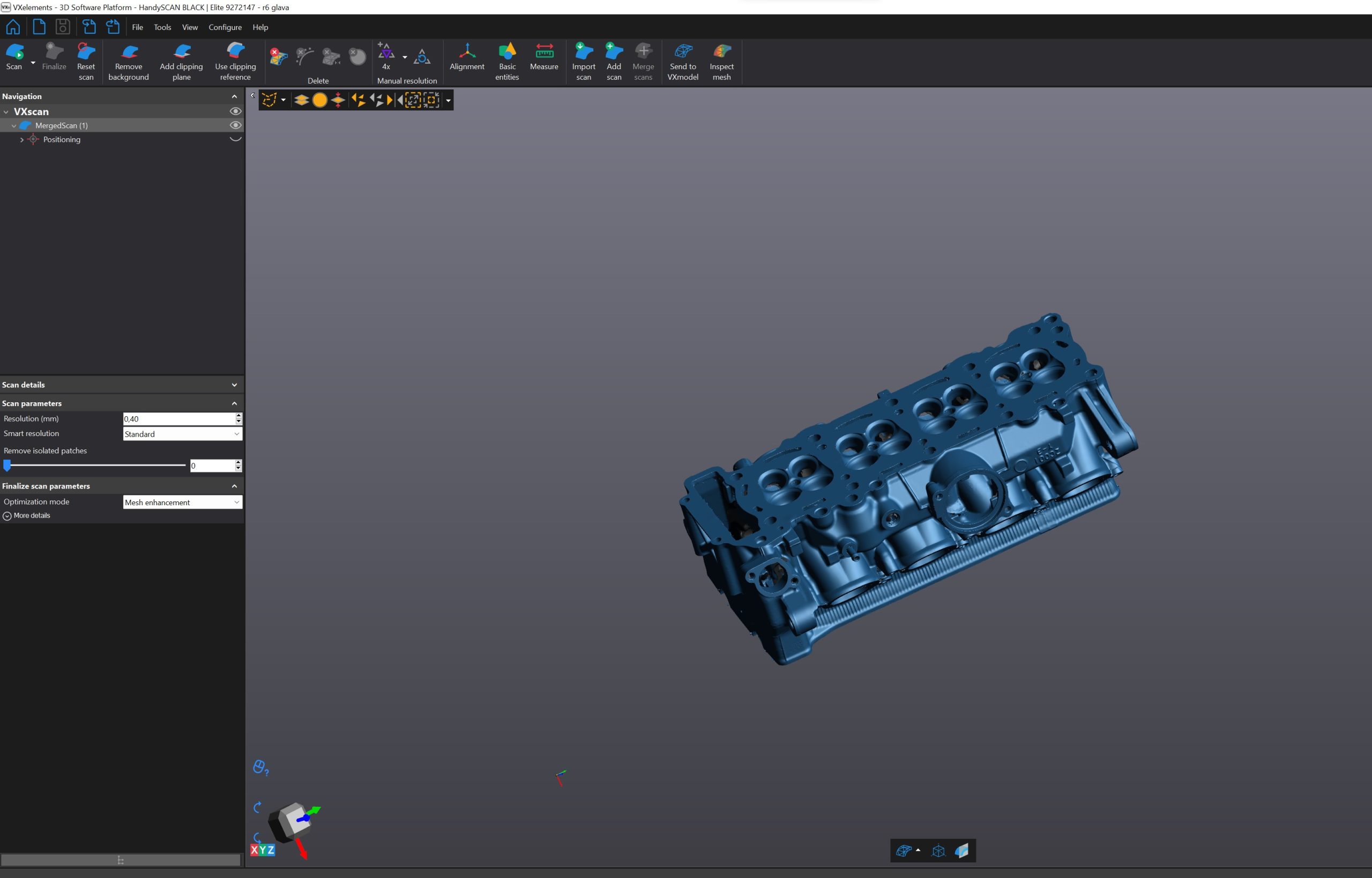

The Creaform 3D Scanner

Precision begins with accurate measurement, facilitated by our state-of-the-art Creaform 3D scanner. Our 3D scanning capabilities enable us to capture precise digital representations of physical objects with unparalleled accuracy and detail. Whether it’s reverse engineering existing components, creating digital models for prototyping, or conducting quality inspections, our Creaform 3D scanner delivers exceptional results, seamlessly integrating into our CNC milling and turning processes to ensure precision craftsmanship at every stage.

Equipped with advanced technology and innovative features, the Creaform 3D scanner offers a range of benefits that enhance our capabilities and elevate our services

Reverse Engineering

Unraveling Complexity, Unlocking Potential

What is it?

Reverse engineering, often referred to as back engineering, is a method used to dissect machines, software, and structures to uncover their design details. It involves breaking down individual components of larger products, serving as a blueprint for recreating them. This approach proves invaluable when sourcing parts becomes impossible from the original manufacturer.

The name “reverse engineering” stems from its process of dissecting designs backward, often challenging due to incomplete manufacturing knowledge. Despite this, reverse engineering serves various industries, offering insight into software, hardware, physical machines, military tech, and biological functions.

The Purpose of Reverse Engineering

The name “reverse engineering” stems from its process of dissecting designs backward, often challenging due to incomplete manufacturing knowledge. Despite this, reverse engineering serves various industries, offering insight into software, hardware, physical machines, military tech, and biological functions.

How Reverse Engineering works?

The reverse engineering process typically involves three key steps:

Application of Reverse Engineering

Reverse engineering finds numerous applications:

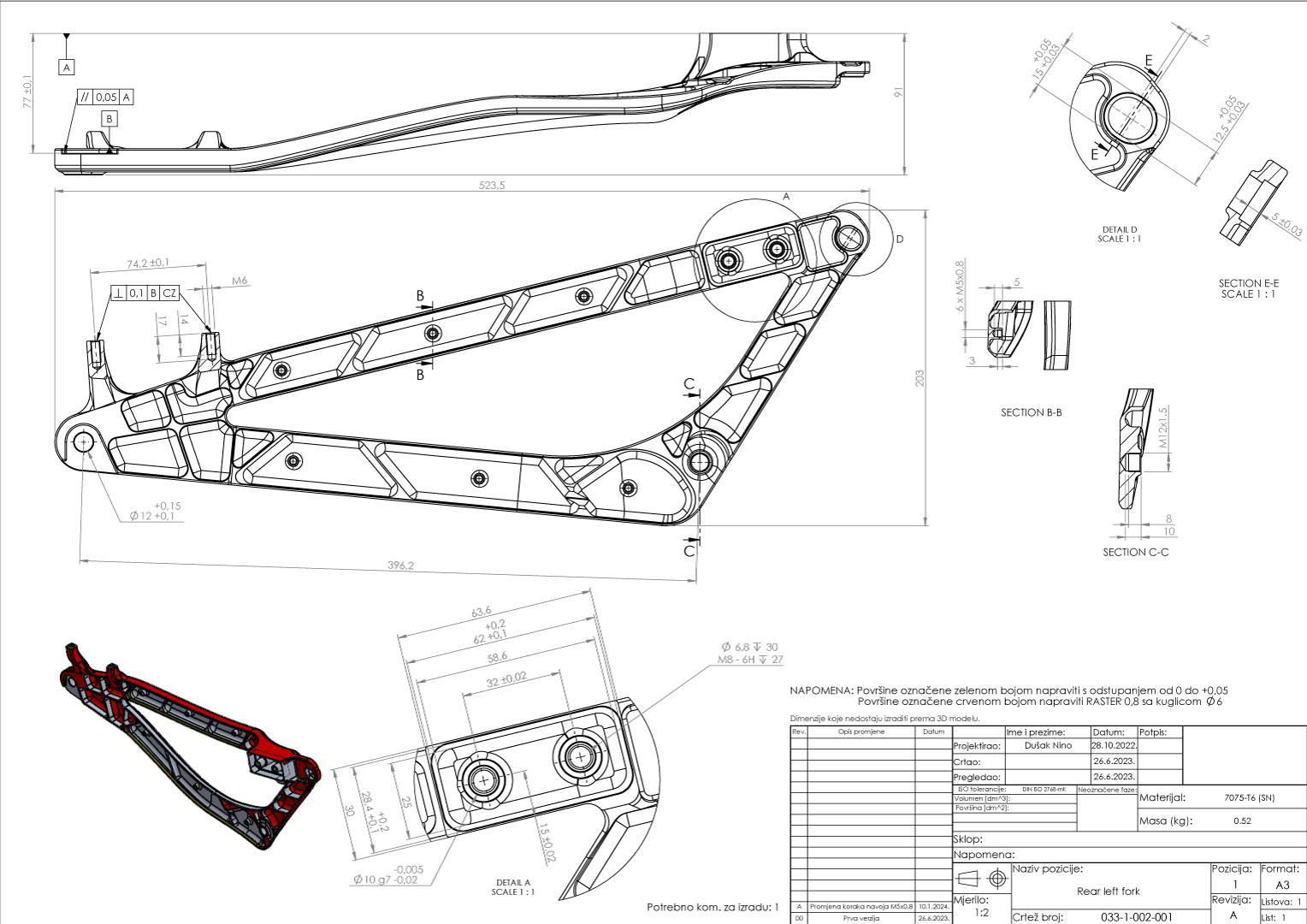

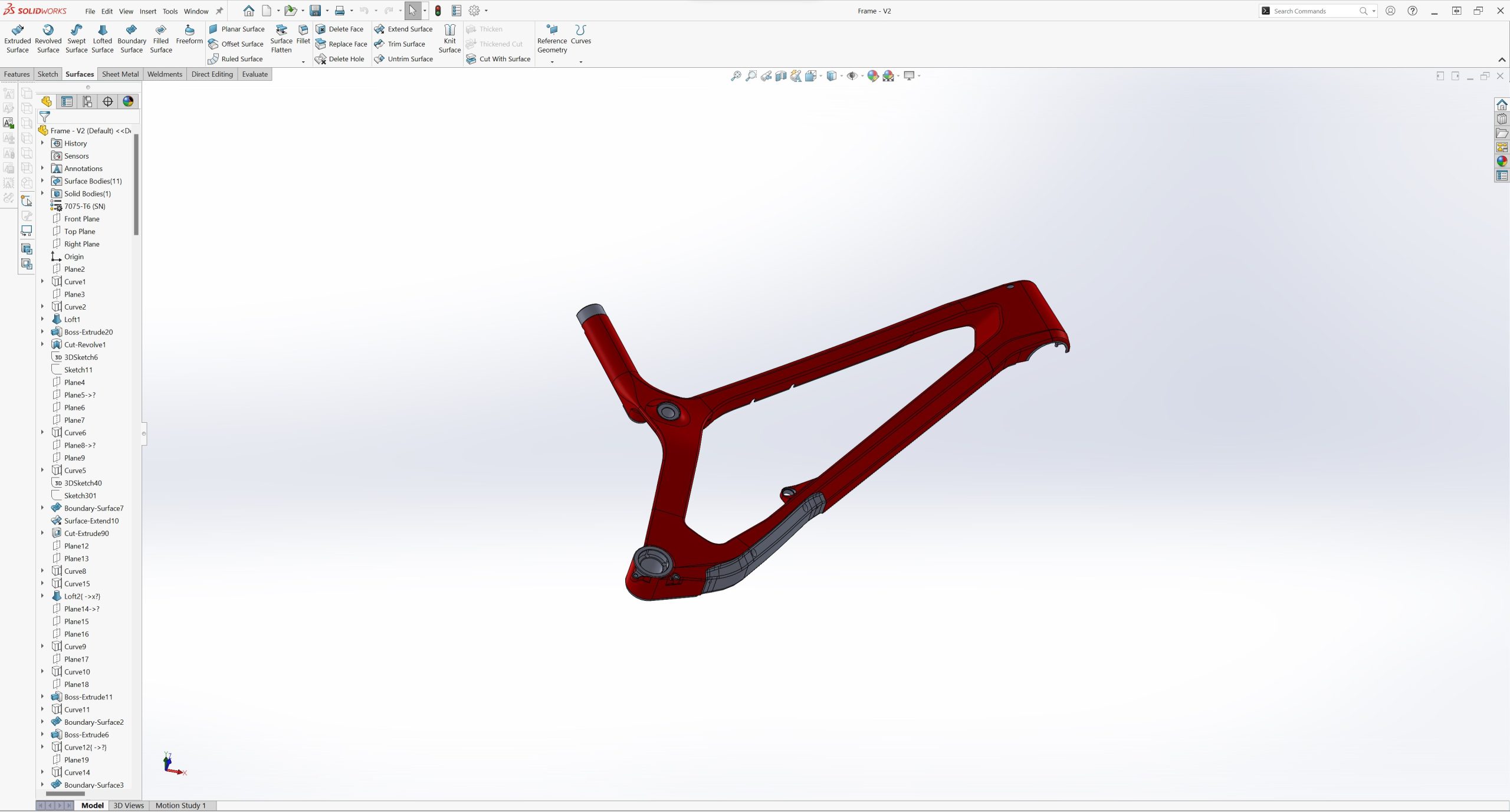

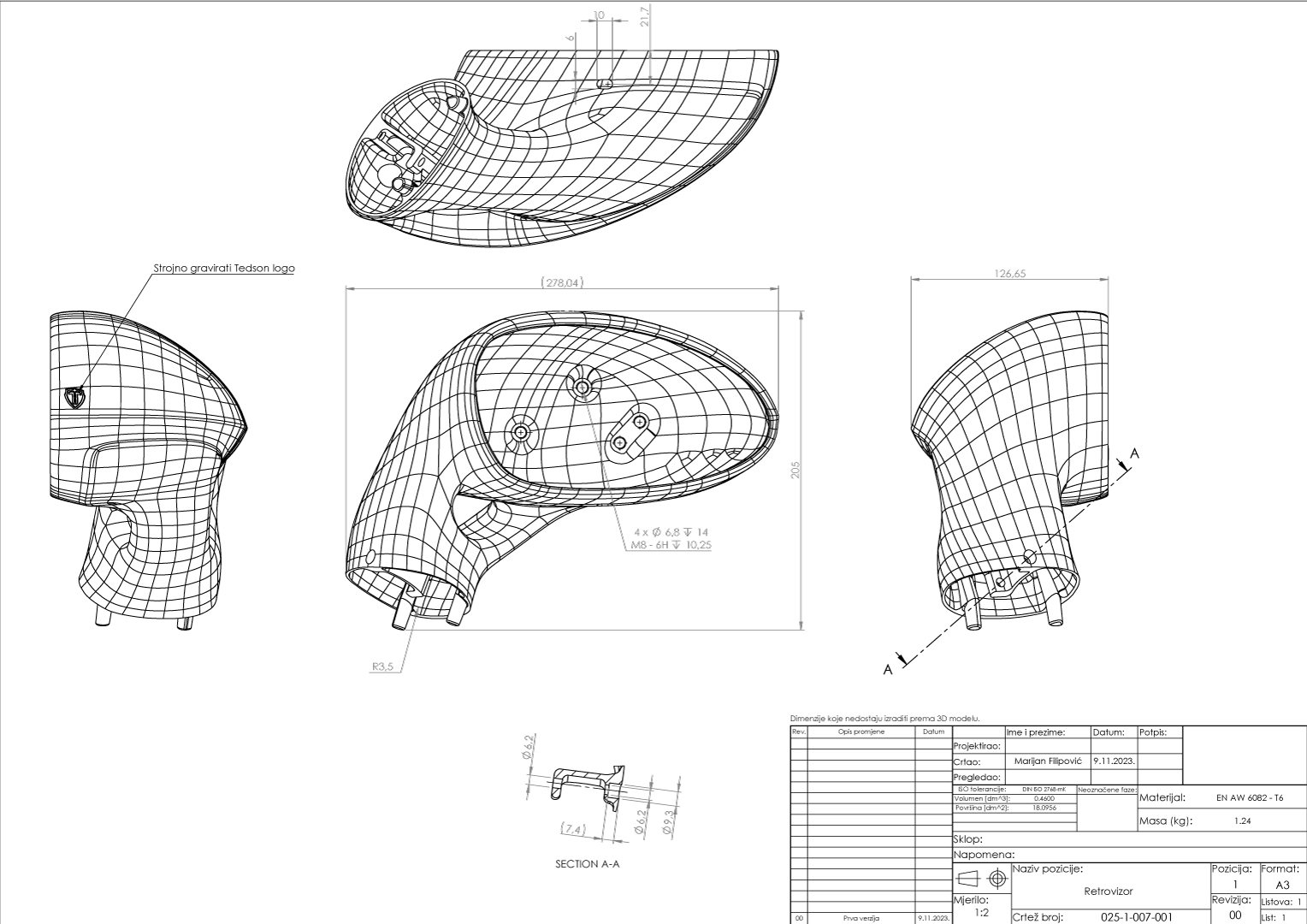

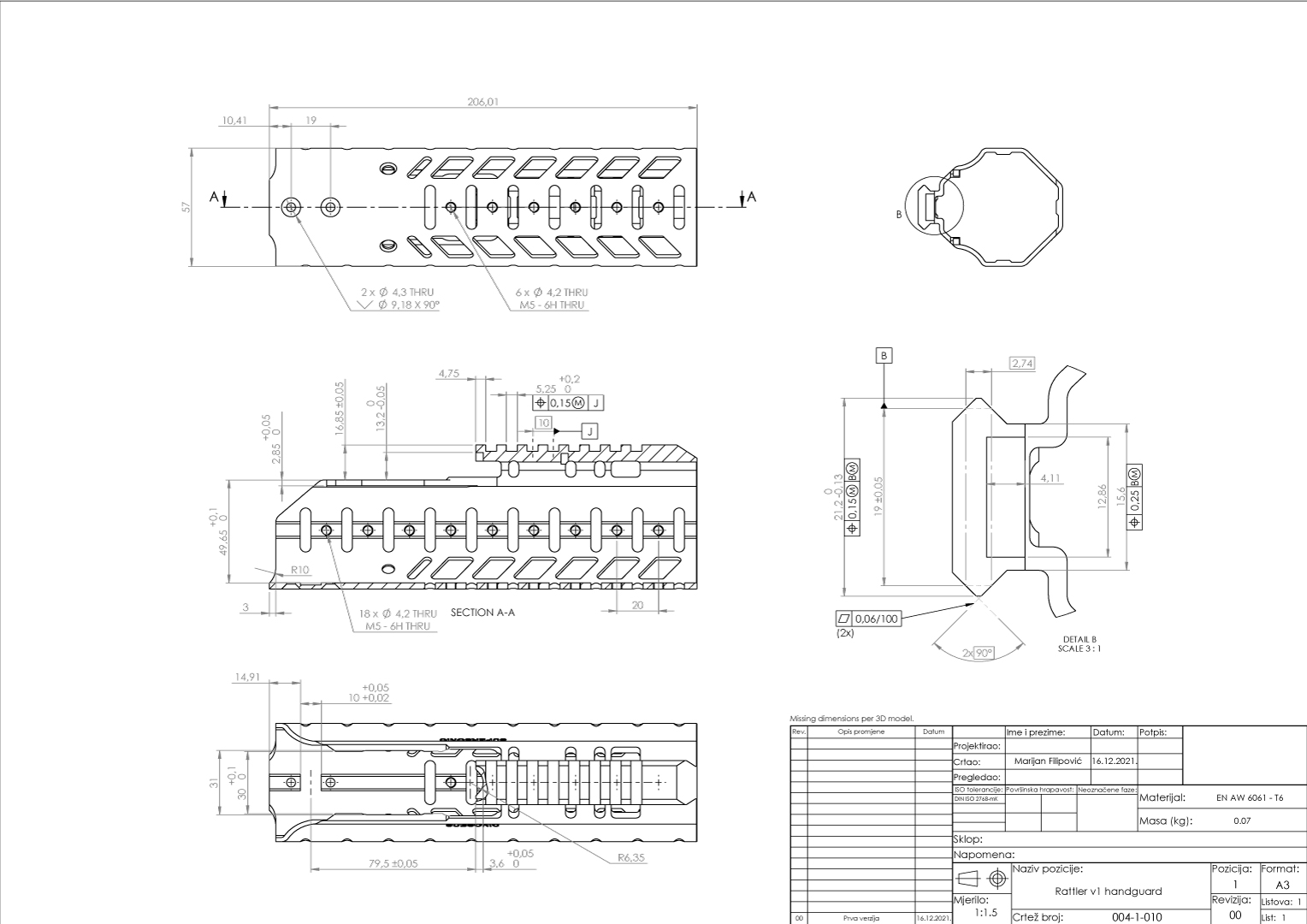

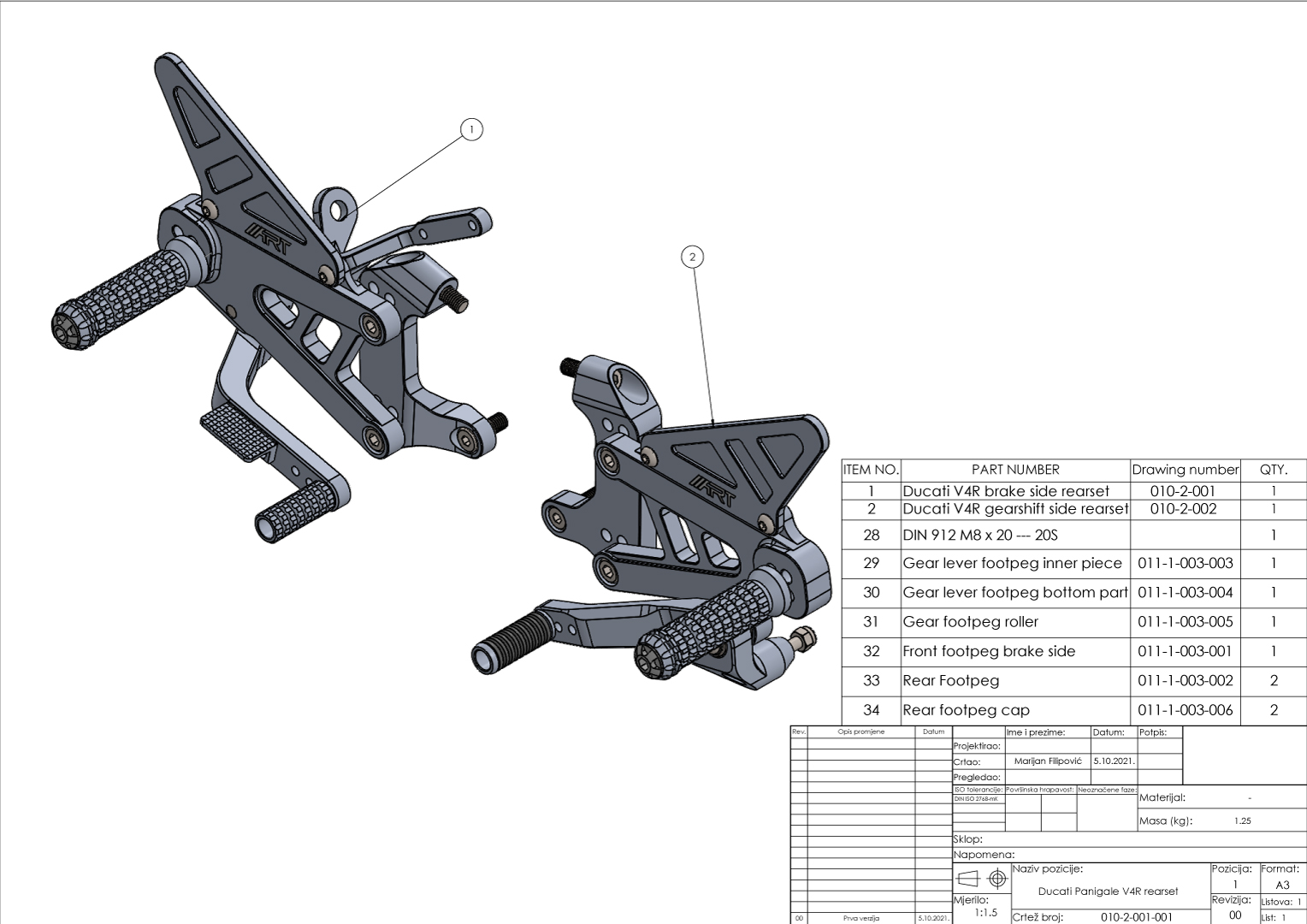

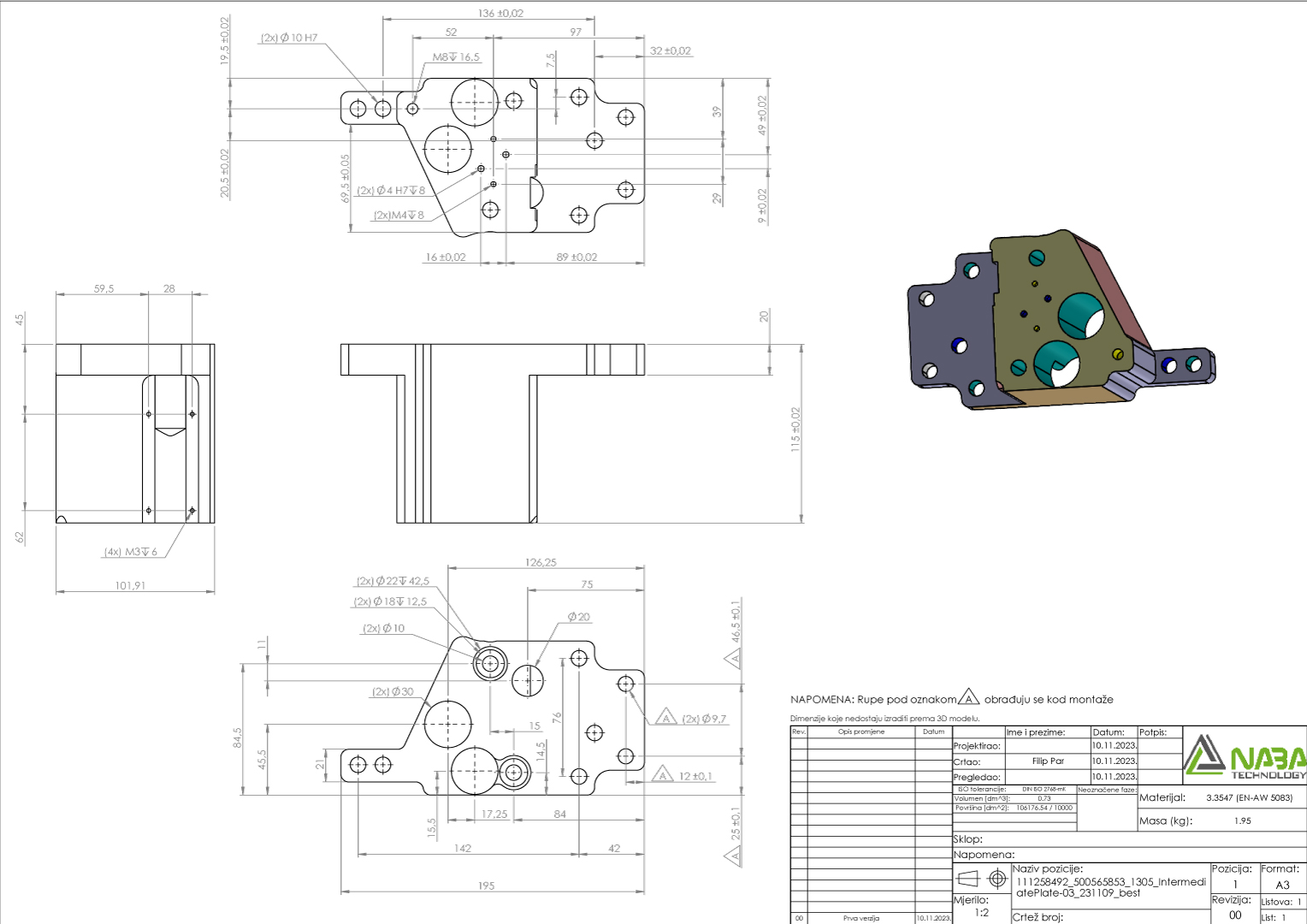

Technical Documentation

Ensuring Quality Every Step of the Way

Precision doesn’t end with production—it extends to documentation. Our meticulous approach to technical documentation ensures that every aspect of the manufacturing process is thoroughly documented, from initial design concepts to final product specifications. By maintaining comprehensive documentation, we provide our clients with peace of mind, transparency, and the assurance that every component meets their exact requirements.

Conclusion

At AlfaTeh GmbH, engineering isn’t just a service—it’s a philosophy. With a focus on innovation, precision, and perfection, we leverage advanced techniques and cutting-edge technology to deliver solutions that redefine the standards of metal fabrication. From R&D and 3D scanning to reverse engineering and technical documentation, our engineering expertise drives continuous improvement and sets new benchmarks for quality and reliability.