Prototyping

In the dynamic landscape of engineering design, prototyping emerges as an essential stage, offering a vital opportunity to explore and perfect concepts before diving into extensive production efforts. This pivotal step not only helps mitigate the risk of costly errors but also accelerates the development process, providing valuable insights and refinements along the way. By embracing prototyping, engineers can confidently navigate the path of innovation while safeguarding resources and timelines.

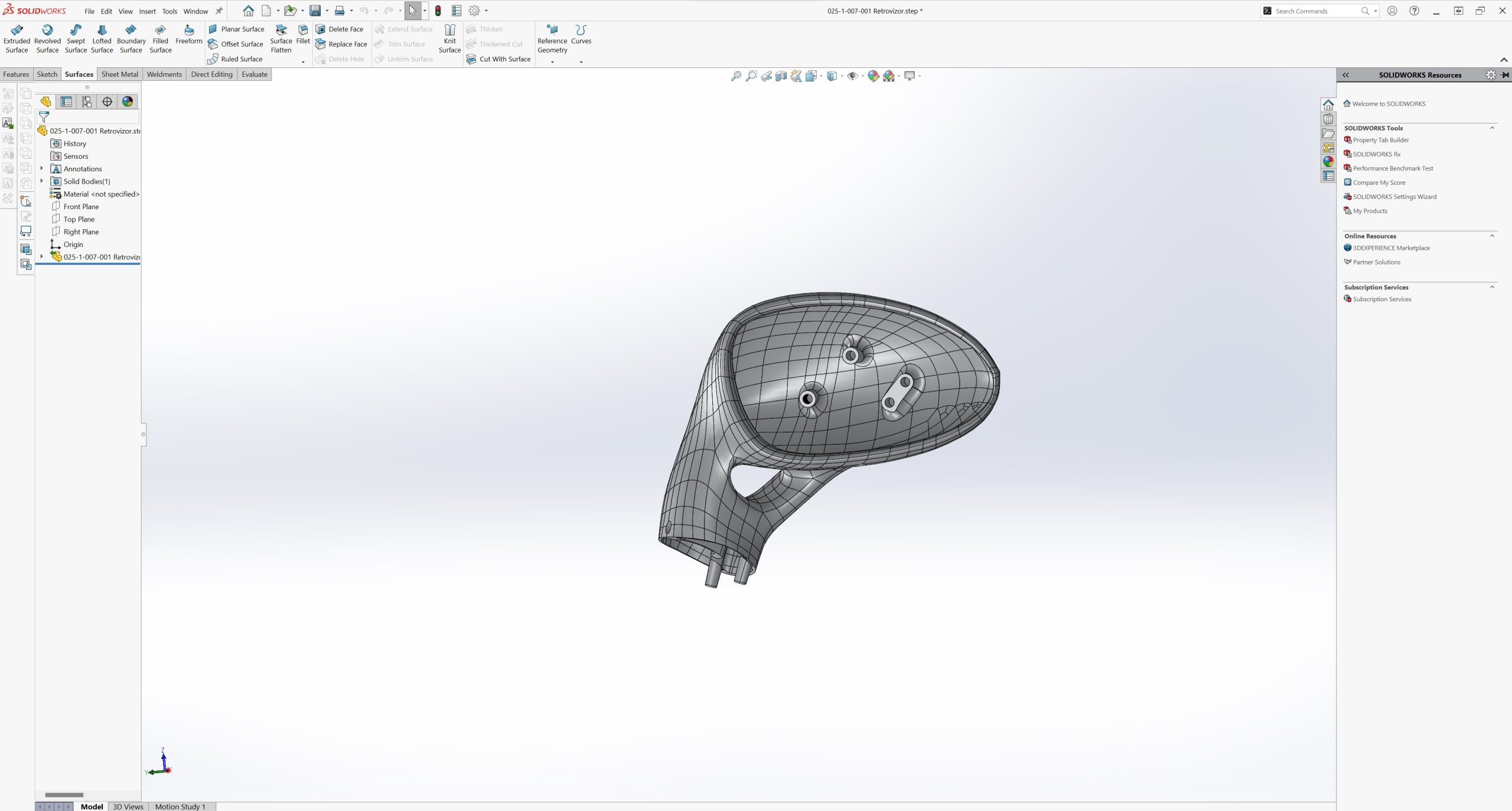

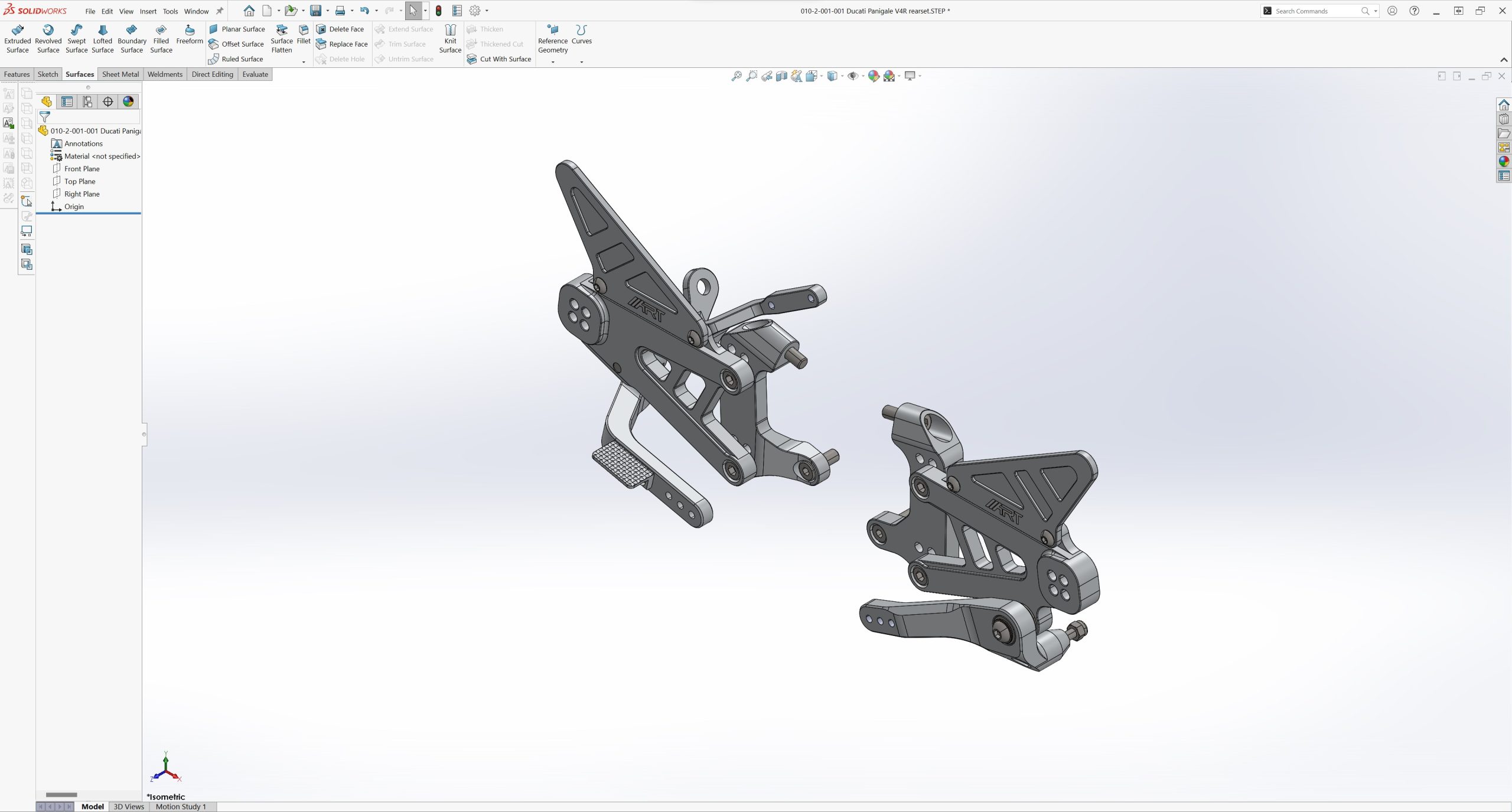

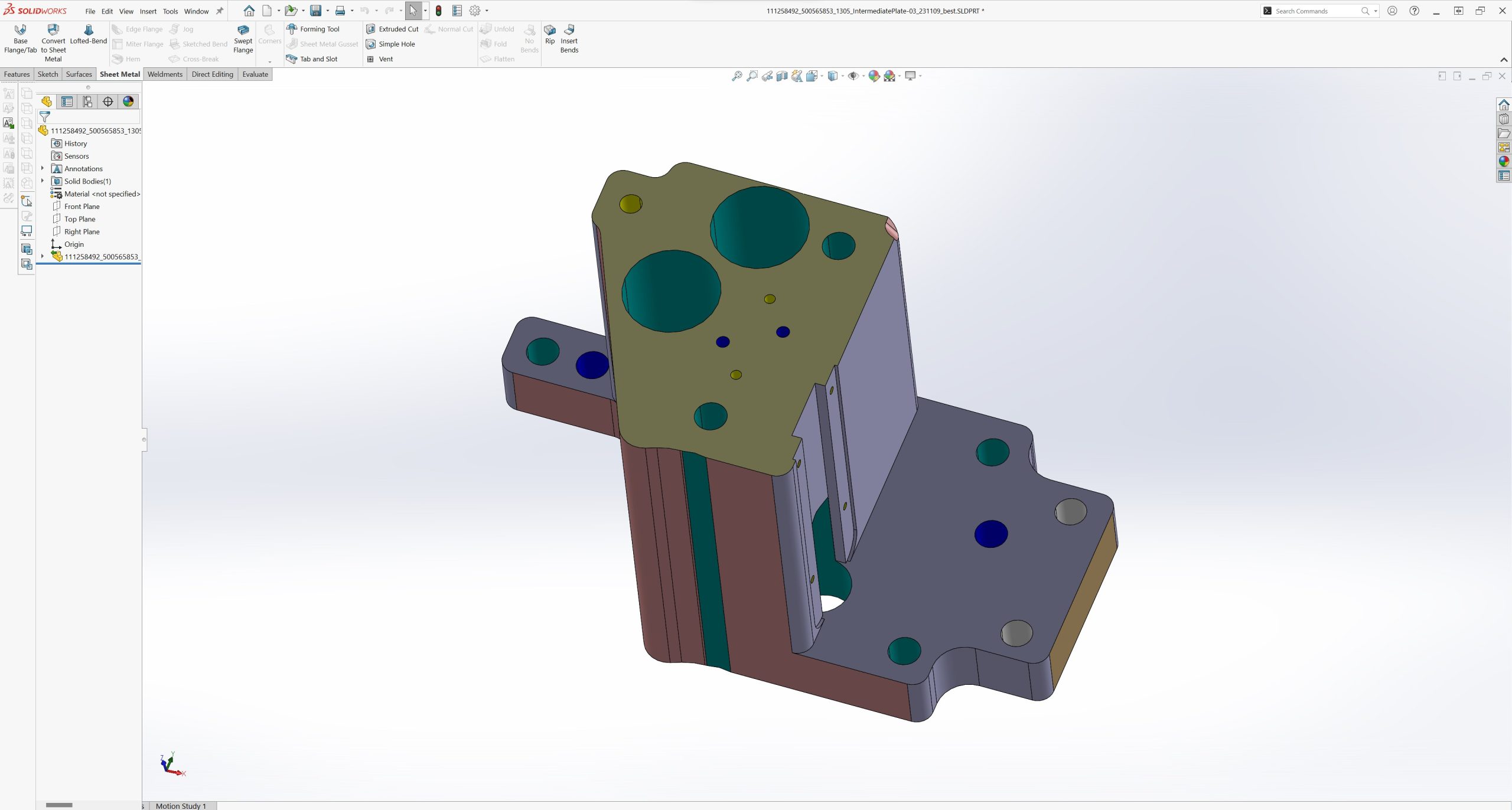

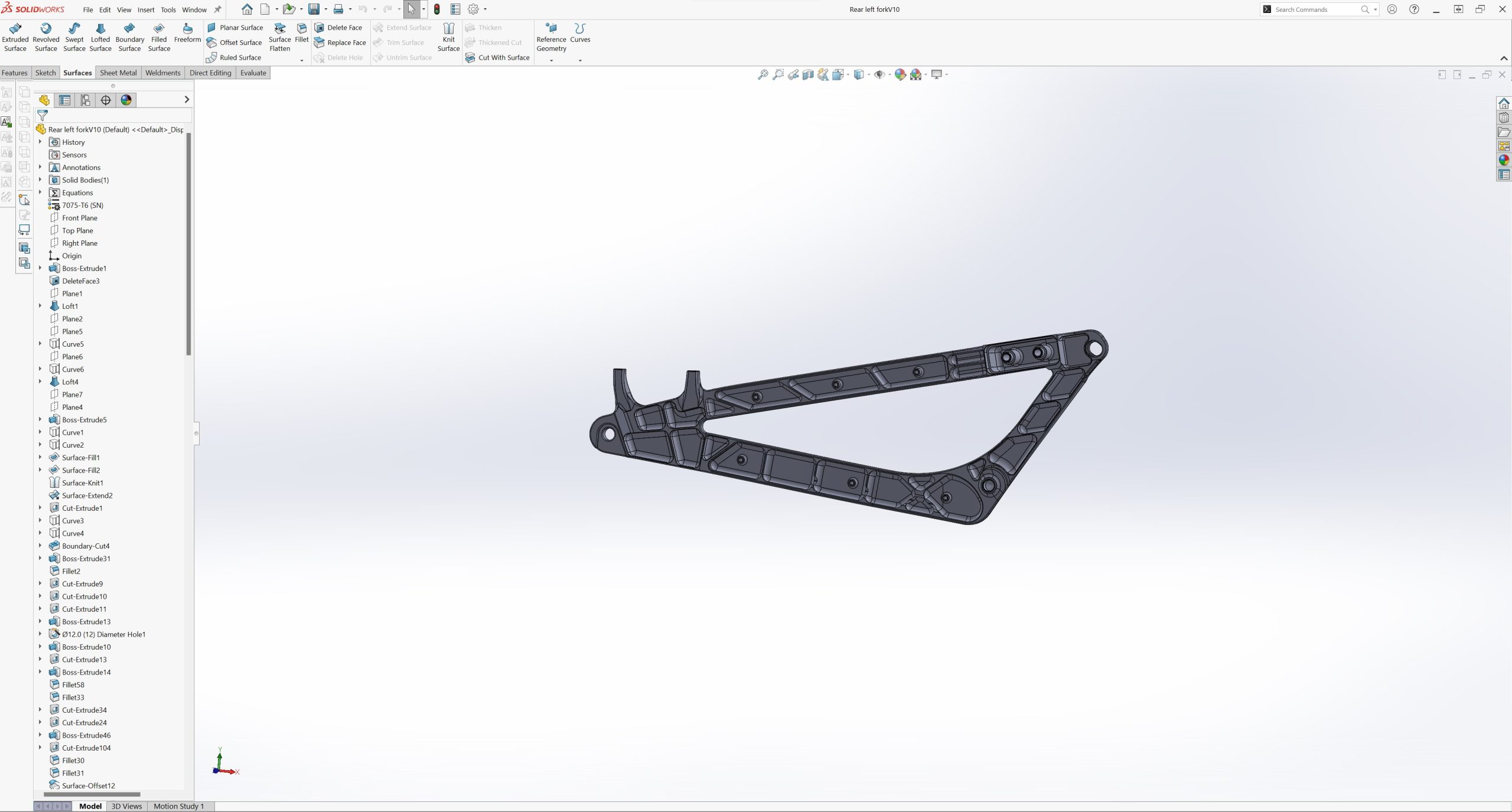

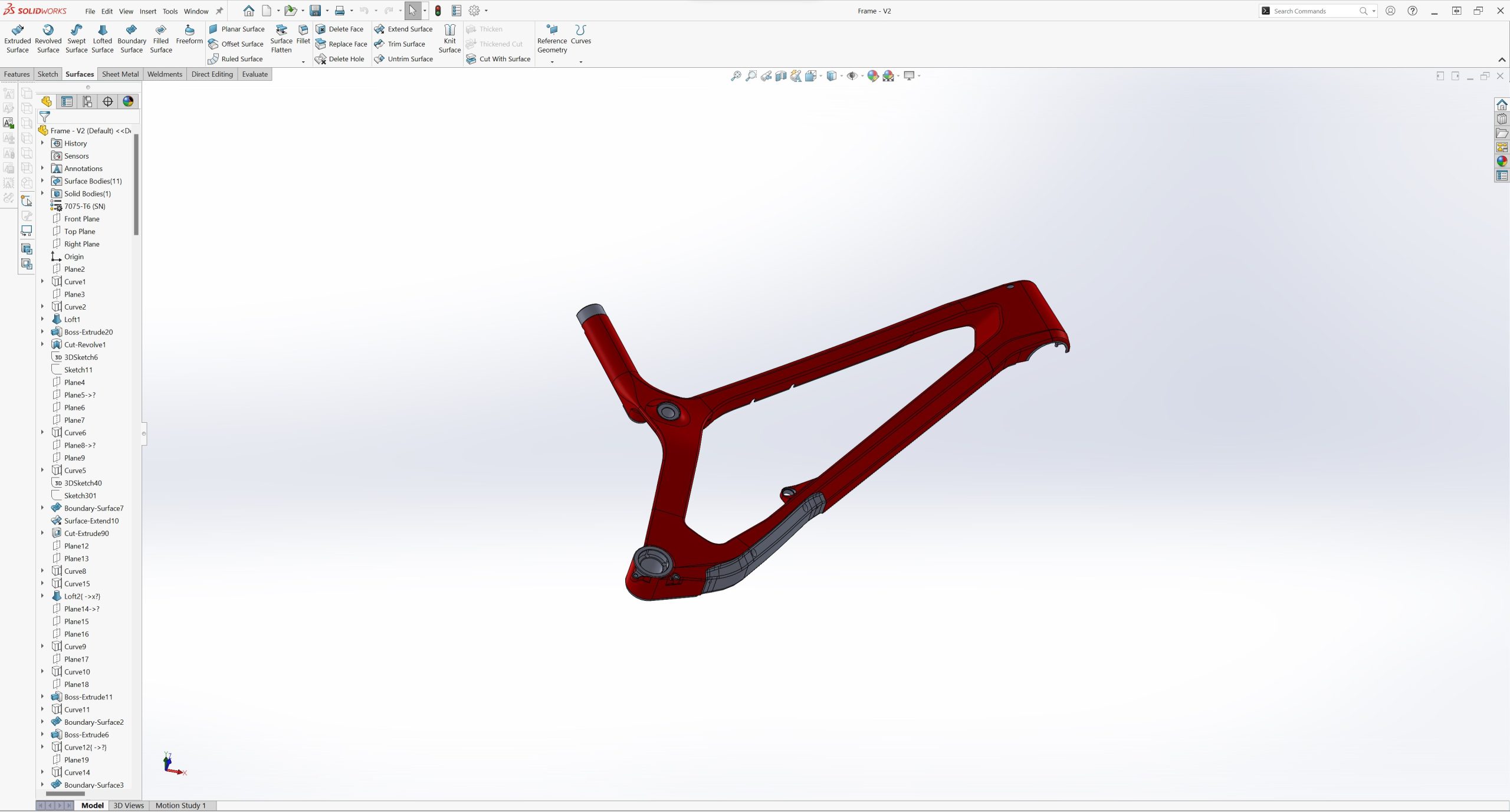

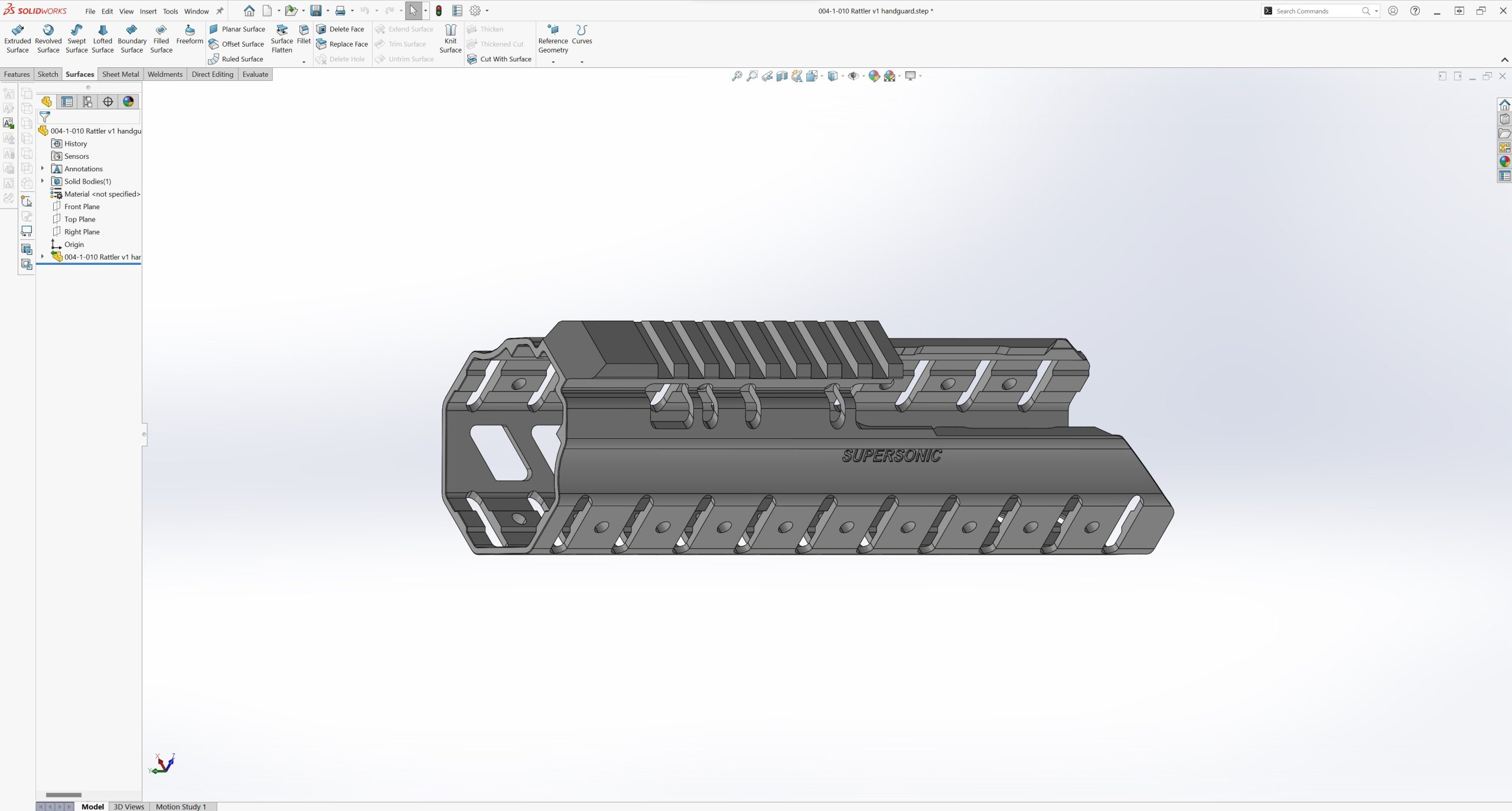

CAD

Design Software

Crafting Designs with Precision

CAD (Computer-Aided Design) software serves as the cornerstone of our prototyping process, enabling our engineers to meticulously craft detailed 3D models of products and systems. With CAD, we not only visualize concepts but also analyze, simulate, and refine designs, ensuring optimal performance and functionality. By harnessing the power of CAD, we streamline the prototyping journey, minimizing errors, and maximizing efficiency.

Simulation

Simulation Software

Predicting Performance with Confidence

Simulation software is an invaluable tool for engineering design, as it allows you to model and predict the behavior and performance of your product or system under various conditions. This software can help you optimize and improve your design, as well as identify and solve potential problems. The benefits of using simulation software for prototyping include increased reliability and safety, enhanced efficiency and effectiveness, and better decision-making and evaluation. Simulation software can detect and eliminate failures and risks, adjust and fine-tune parameters and variables, and provide data and evidence to support evaluation of the design.

3D Printing

3D Printing Prototypes

Bridging Digital and Physical

3D printing is a popular prototyping tool in engineering design, as it allows for the creation of physical models of products or systems from various materials, such as plastic, metal, or resin. This can help validate and verify designs, as well as demonstrate their functionality and feasibility. Utilizing 3D printing for prototyping has numerous benefits, such as speeding up the process by producing models in hours or days instead of weeks or months. It also promotes creativity and innovation by allowing experimentation with different shapes, sizes, and features. Additionally, 3D printing significantly reduces waste and environmental impact by using less material and energy than traditional manufacturing methods

Precision and Accuracy

Our Hallmark

At AlfaTeh GmbH, precision and accuracy are ingrained in our DNA. With state-of-the-art equipment and a relentless pursuit of perfection, we meticulously craft each prototype to meet exacting specifications. From intricate mechanical parts to complex product designs, we uphold the highest standards of quality, ensuring flawless execution at every turn.

Cost-Efficiency

Nurturing Ideas, Minimizing Risks

Prototyping isn’t just about testing designs—it’s about nurturing ideas and minimizing risks. Through iterative development cycles, we empower our clients to explore, refine, and validate their concepts without committing to costly production runs. This iterative approach not only accelerates time-to-market but also fosters innovation, enabling us to deliver solutions that are as cost-effective as they are cutting-edge.

Collaboration

Partnering for Success

Collaboration is at the heart of everything we do. Our multidisciplinary team of engineers, designers, and technicians works hand-in-hand with clients, valuing their input and insights at every stage of the prototyping journey. Together, we co-create solutions that transcend expectations, leveraging collective expertise to bring visions to life with precision and passion.

Material Flexibility

Tailoring Solutions to Your Needs

From prototyping plastics to industrial-grade metals, we offer a diverse range of materials to match your project’s unique requirements. Whether you’re exploring novel concepts or refining existing designs, our material flexibility ensures that your prototypes are optimized for performance, durability, and functionality across diverse industries and applications.

Scalabilitiy

Seamlessly Transitioning to Production

Once your prototype is perfected, our seamless integration with manufacturing capabilities ensures a smooth transition to full-scale production. By eliminating the need for separate partners, we streamline the production process, saving time, resources, and effort while maintaining the same level of precision and quality that defines our prototyping solutions.