Pharma & Medical

CNC Machining Applications in the Medical Industry

In recent years, Computer Numerical Control (CNC) machining has revolutionized the way medical devices and components are manufactured. From surgical instruments to implantable devices, CNC machining offers precision, reliability, and customization crucial for the demanding requirements of the medical sector.

Precision Engineering for Critical Components

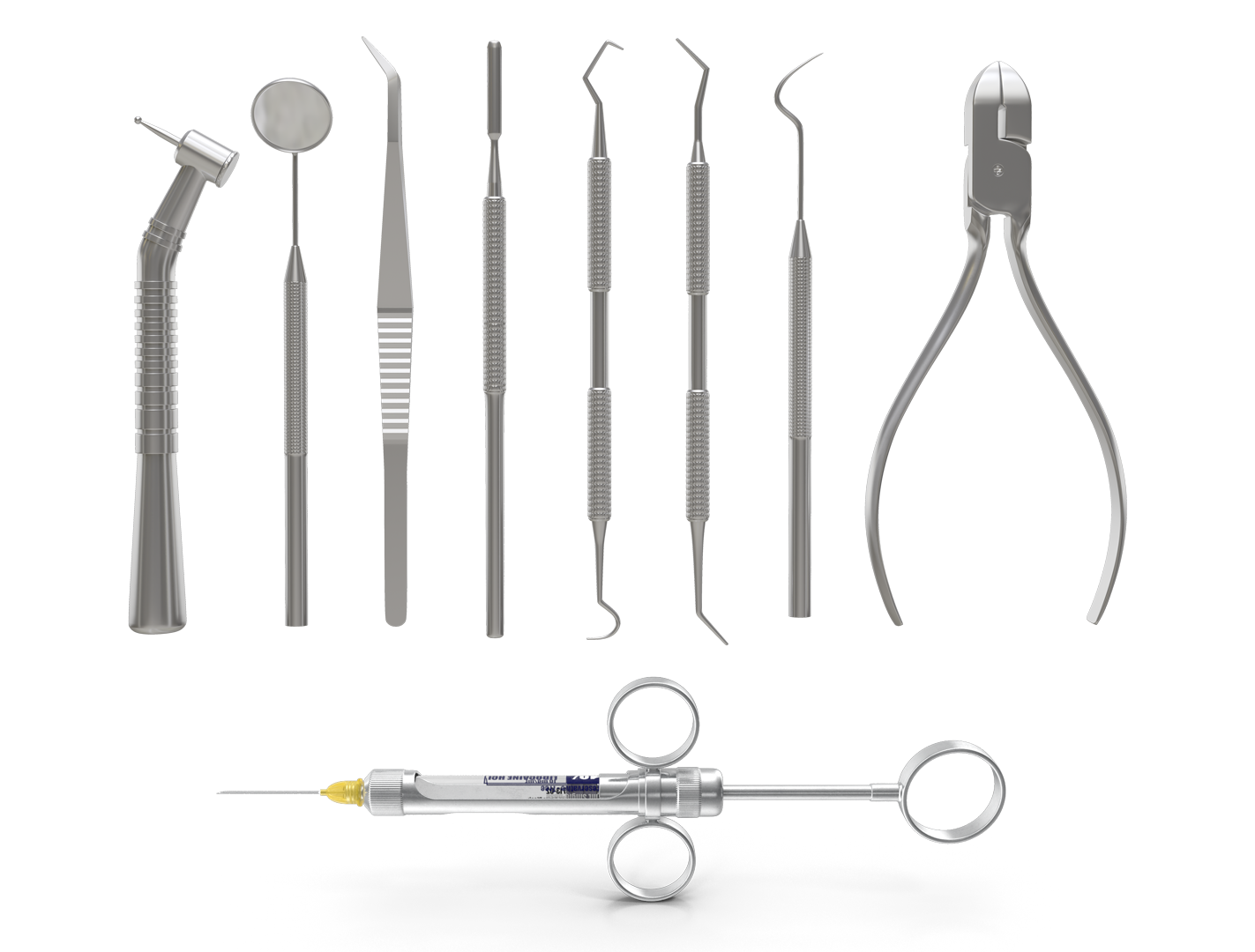

One of the primary advantages of CNC machining in the medical field is its ability to produce intricate and precise components with tight tolerances. This precision is vital for critical medical devices such as pacemakers, prosthetic limbs, and surgical instruments. CNC machining ensures that these components meet exact specifications, guaranteeing their effectiveness and safety in medical applications.

Customization for Patient-Specific Solutions

Every patient is unique, and their medical needs often require customized solutions. CNC machining enables the production of patient-specific medical devices and implants tailored to individual anatomical requirements. Whether it’s orthopedic implants, dental prosthetics, or patient-specific surgical guides, CNC machining empowers medical professionals to deliver personalized care with enhanced outcomes.

Material Versatility for Diverse Applications

The medical industry demands a wide range of materials with varying properties to meet the diverse needs of different applications. CNC machining excels in working with a plethora of materials, including metals like titanium, stainless steel, and cobalt-chrome, as well as biocompatible plastics and ceramics. This versatility allows for the fabrication of implants, instruments, and components optimized for specific medical functions and environments.

Cost-Effective Production with High Efficiency

In addition to precision and customization, CNC machining offers cost-effective production solutions for medical device manufacturers. The automation and efficiency of CNC processes minimize material waste and reduce production time, resulting in lower overall manufacturing costs. This cost-effectiveness enables greater accessibility to high-quality medical devices and promotes innovation within the medical industry.

Conclusion

CNC machining has emerged as a cornerstone technology in the medical industry, facilitating the production of precise, customized, and cost-effective medical devices and components. Its versatility, efficiency, and adherence to quality standards make it indispensable for meeting the evolving needs of modern healthcare. As the medical landscape continues to advance, CNC machining will undoubtedly play a pivotal role in driving innovation and improving patient care.

Mobil:

Mobil: